After various phone calls on day one, we were delighted that one of the main OUP printers, the CPI Group, could print the Bible to meet the proposed deadlines, and they also had the 60 gsm paper we wanted in stock! We were set on 60 gsm as we needed to find a balance between traditional bible paper and something with a bit of substance to it for the printing method.

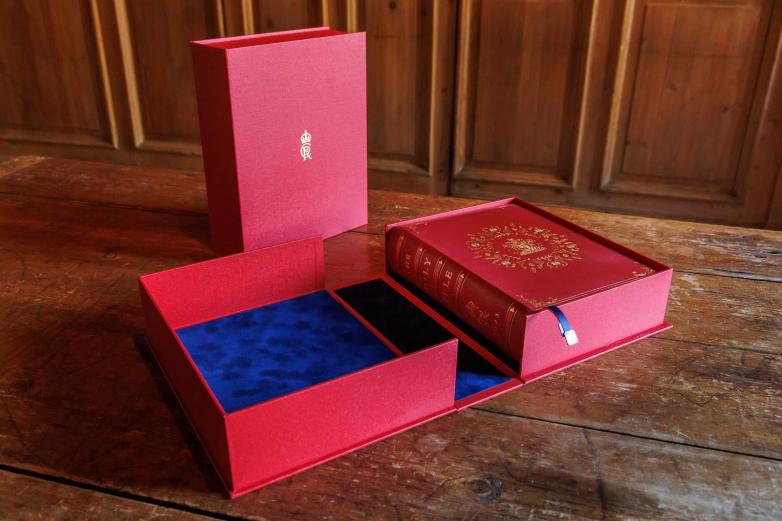

On day two I made a phone call to London bookbinders Shepherds, Sangorski & Sutcliffe. There followed a wonderfully reassuring conversation with Managing Director, Alison Strachan, who confirmed, despite the tight schedule, that Shepherds would be very much interested in being the binder for the Coronation Bible. I then visited Shepherds, alongside OUP Editorial and Design teams, at the earliest opportunity, during which the specification details, materials, and schedule started to take shape.

Time was of the essence for this project. It was important to get the printed sheets to Shepherds on time, to select the binding materials without delay, and for the Design team to create the cover design, and the additional content for the text.

CPI printed the Bible by offset litho in record time at their Chippenham plant. A big thank you to James Alvis, Nicola King, and all those at CPI who ensured the printing quality and deadline was met.

A massive thanks too goes to Alison Strachan and the wonderful team at Shepherds, who worked tirelessly to make the deadline. Much was gained from collaboration between Shepherd’s and OUP’s Design team to produce the beautiful result.

Like with all successful projects, it was down to the dedication of a team of experts in their field. It proved to be a dream team, for what seemed, at times, like a dreamlike event!

This is the second of three guest posts by people involved in the creation of the Coronation Bible. Part I appeared yesterday, Part III will appear tomorrow.